|

||

|

The S-Curve function is used in Yaskawa drives to soften the initial start and end periods of the acceleration and deceleration times to minimize abrupt shock to the load. For example, a conveyor belt application with bottles may require longer S-curve times to prevent the bottles from tipping over when the drive starts and stops the motor. |

|

|||||||||||

|

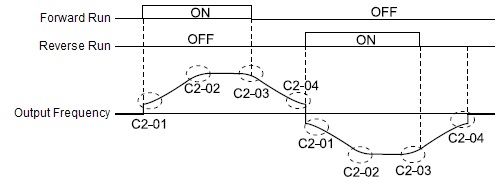

Adjust the S-curve times as needed.

The S-curve times will increase the total acceleration and deceleration times as shown below.

|

|

||

| Troubleshooting an oL2 (Drive Overload) Fault

Troubleshooting an oV DC Bus Overvoltage Fault |

|

||

| All Drives, |

|

||

| Advanced Random Rotary Knife with Cam Blend, Air Compressor, Blister pack Thermoformer, Cartoner, Centrifuge, Conveyor, Crane/Hoist, Dynamometer, Elevators and Escalators, Extrusion, Fans/Blowers, Feed To Length, General Machinery, HVAC, Irrigation, Labeler, Laundry, Linear Flying Shear, Machine Tool, Mixer, Other, Packaging, Palletizer, Precision Grinding, Pump, Punch Press, Rotary Knife, Rotary Placer, Rotary Table Indexer, Screw Feeder, Semiconductor, Solar Cell Tabbing and Bussing, Solar - Textured Etching, Synch-Belt, Textile, Winding, |

| Last Modified Date: 07-22-2024 |

|

|