|

||

|

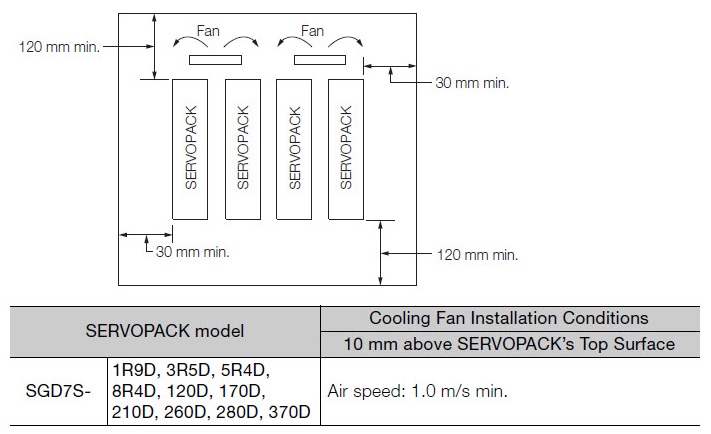

The 400V model SERVOPACK has mounting space specifications for multi-axis cabinet installations which do not require space between SERVOPACKs that are mounted side-by-side. However, space is required for the end SERVOPACKs to provide adequate air movement in a cabinet. (See last picture in Resolution section) |

|

||

|

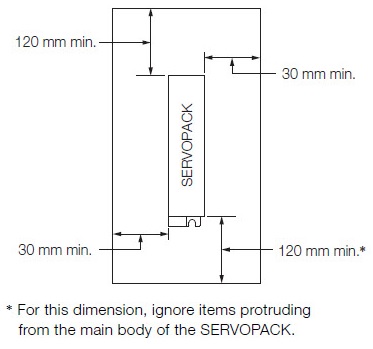

Follow the guidelines below when mounting Sigma 7 SERVOPACKs inside of a cabinet. Installing One SERVOPACK in a Control Panel The 200V and 400V Sigma 7 SERVOPACKs have the same space requirements when mounting only ONE SERVOPACK inside a cabinet or control panel.

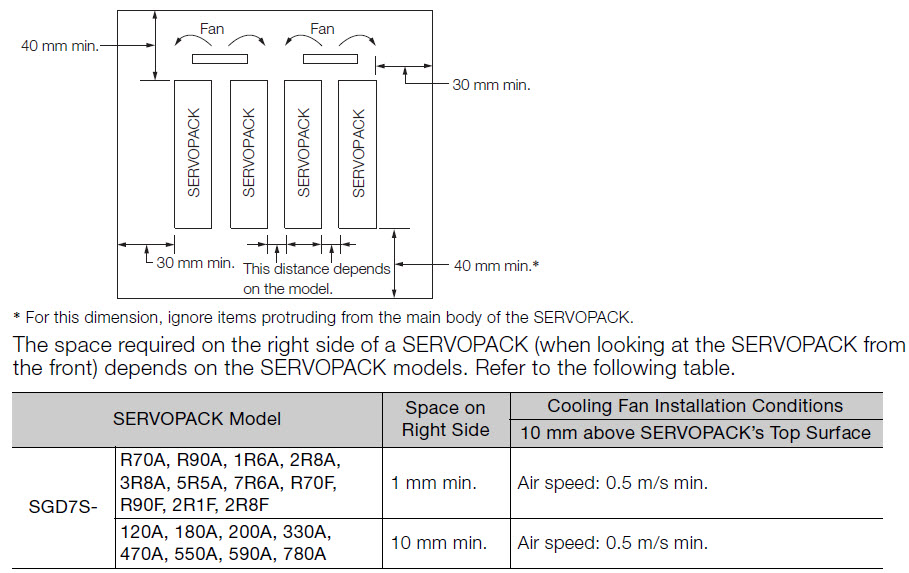

Installing More than One SERVOPACK in a Control Panel The 200V and 400V Sigma 7 SERVOPACKs have different space requirements when mounting more than one inside a cabinet or control panel. Note that the top and bottom distances may vary. Refer to the relevant user's manuals for additional information.

The 400V Sigma 7 SERVOPACKs has no space requirement inbetween SERVOPACKS, but does have a space requirement along the sides.

Note:

The referenced SGD7S manuals can be found here: |

|

||

| Sigma-7 Series, |

|

||

| Advanced Random Rotary Knife with Cam Blend, Air Compressor, Blister pack Thermoformer, Cartoner, Centrifuge, Conveyor, Crane/Hoist, Dynamometer, Elevators and Escalators, Extrusion, Fans/Blowers, Feed To Length, General Machinery, HVAC, Irrigation, Labeler, Laundry, Linear Flying Shear, Machine Tool, Mixer, Other, Packaging, Palletizer, Precision Grinding, Pump, Punch Press, Rotary Knife, Rotary Placer, Rotary Table Indexer, Screw Feeder, Synch-Belt, Textile, Winding, |

| Last Modified Date: 07-22-2024 |

|

|