|

||

|

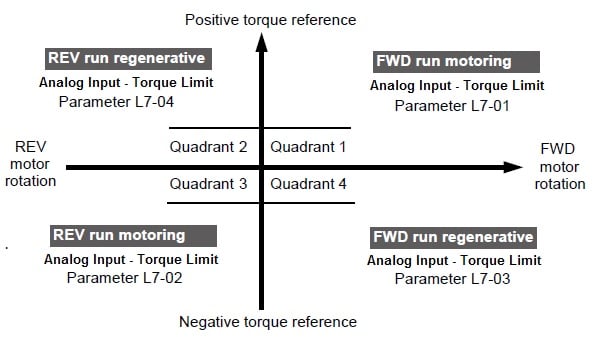

The GA800, GA500, HV600, A1000, U1000, and V1000 drives have the capability of using an analog input to set a general torque limit. Note: A torque limit is only available in OLV, CLV, AOLV, AOL/PM, CLV/PM, and EZOLV control modes. |

|

||

|

To set a general torque limit with an analog input, assign an analog input (A1, A2, or A3) and set H3-0x = 15 (general torque limit).

|

|

||

| Changing Motor Direction in Torque Control

Using Torque Control on the A1000, U1000 or GA800 Drives Viewing Motor Torque Feedback |

|

||

| GA800, GA800 Configured, GA500, HV600, HV600 Bypass, HV600 Configured, A1000, A1000 Configured, L1000, U1000 Industrial, V1000, V1000-4X, |

|

||

| Advanced Random Rotary Knife with Cam Blend, Air Compressor, Blister pack Thermoformer, Cartoner, Centrifuge, Conveyor, Crane/Hoist, Dynamometer, Elevators and Escalators, Extrusion, Fans/Blowers, Feed To Length, General Machinery, HVAC, Irrigation, Labeler, Laundry, Linear Flying Shear, Machine Tool, Mixer, Other, Packaging, Palletizer, Precision Grinding, Pump, Punch Press, Rotary Knife, Rotary Placer, Rotary Table Indexer, Screw Feeder, Semiconductor, Solar Cell Tabbing and Bussing, Solar - Textured Etching, Synch-Belt, Textile, Winding, |

| Last Modified Date: 07-22-2024 |

|

|