|

||

|

An A.C90 or A.C9 error is related to an issue with encoder communications or connection. SERVOPACKs require encoder feedback from a Yaskawa servomotor encoder within the same size. Note:

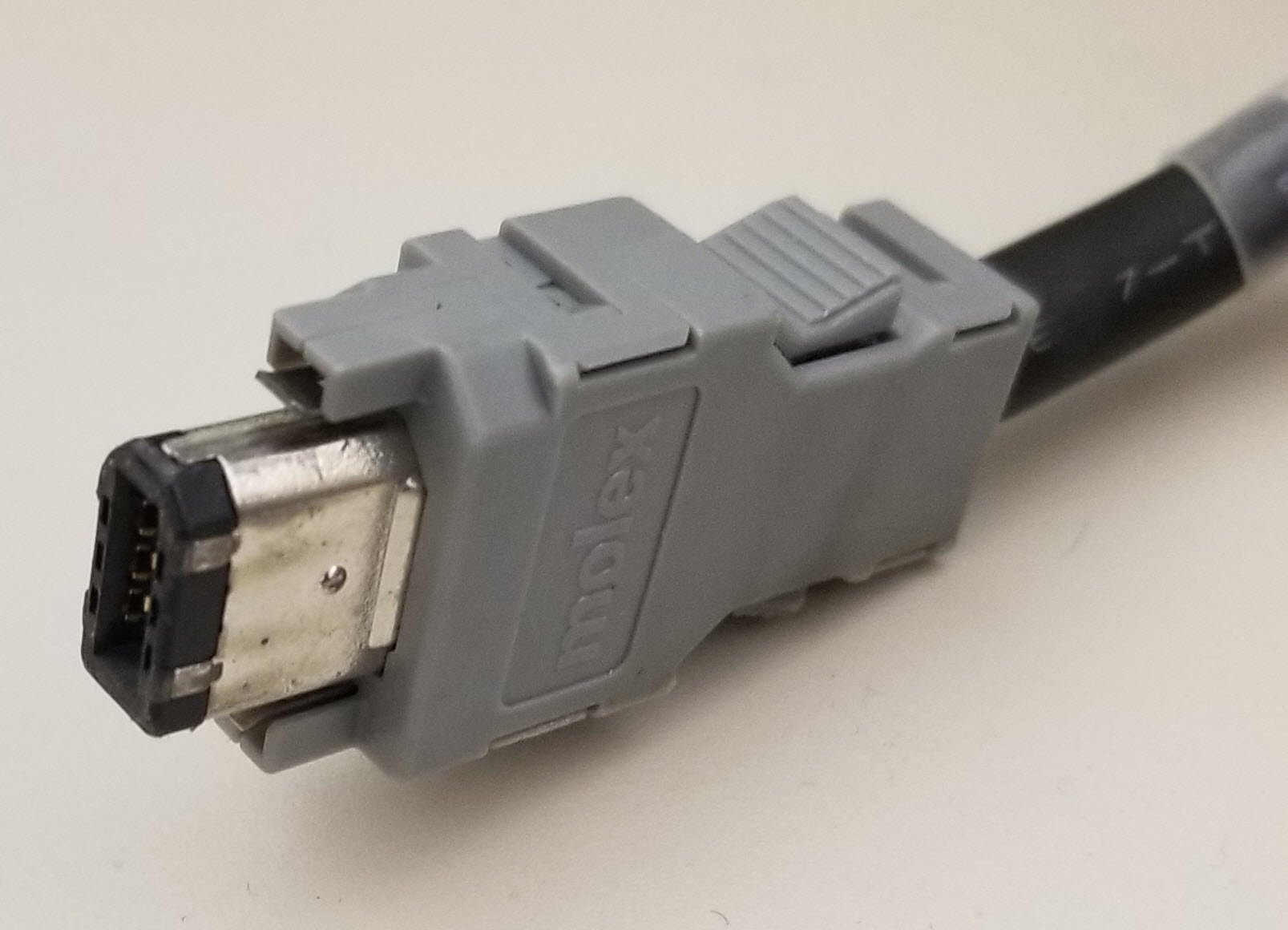

The image below shows the CN2 connector on the servomotor encoder cable.

|

|

||

Refer to the product's user manuals (SERVOPACK and servomotor) for additional details, causes, and resolutions. |

|

||

| SGD7S Analog, SGAGS, SGDS, FSP, SGD7S EtherCAT, SGDV, SGDG, SGD7S Mechatrolink-III, SGLC, SGDH, SGLFW with Sigma-5, SGDJ, Sigma-7Siec - Servopack, SGLGW with Sigma-5, SGDK, SGD7W EtherCAT, SGD7W Mechatrolink-III, SGLTW with Sigma-5, SGDM, SGLF2, SGLFW with Sigma-7, SGMAV, SGMAH, SGLGW with Sigma-7, SGMCS with Sigma-5, SGMAJ, SGLTW with Sigma-7, SGMCV with Sigma-5, SGMBH, SGM7A, SGMGV, SGMCS with Sigma-2, SGM7D, SGMJV, SGMDH, SGM7E Direct Drive, SGM7F, SGMMV, SGMDM, SGM7G, SGMSV, SGMGH, SGM7J, SGMVV, SGMKS, SGM7P, SGT1F, SGMPH, SGMCS with Sigma-7, SGTMF, SGMPS, SGMCV with Sigma-7, SGTMM, SGMSH, S7G, Sigma-5-SD, SGMUH, S7A, SigmaLogic, SGMVH, S7P, SGDV Mini, Sigma Trac, S7J, Sigma Trac SGT, SigmaLogic7 Compact, Sigma Trac STF, SigmaLogic7 Modbus, SGD7S EtherCAT with FSoE, |

|

||

| Advanced Random Rotary Knife with Cam Blend, Air Compressor, Blister pack Thermoformer, Cartoner, Centrifuge, Conveyor, Crane/Hoist, Dynamometer, Elevators and Escalators, Extrusion, Fans/Blowers, Feed To Length, General Machinery, HVAC, Irrigation, Labeler, Laundry, Linear Flying Shear, Machine Tool, Mixer, Other, Packaging, Palletizer, Precision Grinding, Pump, Punch Press, Rotary Knife, Rotary Placer, Rotary Table Indexer, Screw Feeder, Semiconductor, Solar Cell Tabbing and Bussing, Solar - Textured Etching, Synch-Belt, Textile, Winding, |

| Last Modified Date: 10-16-2024 |

|

|