|

|||||||||||||||||||

|

GA800, FP605, GA500, A1000, V1000, or U1000 drives have the ability to automatically switch acceleration and deceleration times at a specific frequency level set in parameter C1-11. Refer to the table below for the acceleration and deceleration settings based on Motor 1 / Motor 2 selection.

For example, using Motor 1 to ramp up from 0Hz to 45Hz in 15 seconds and 45Hz to 60Hz in 25 seconds, set C1-11 = 45Hz to specify the switching frequency then calculate the proper C1-07, C1-01, C1-02, and C1-08 values. |

|||||||||||||||||||

|

||

|

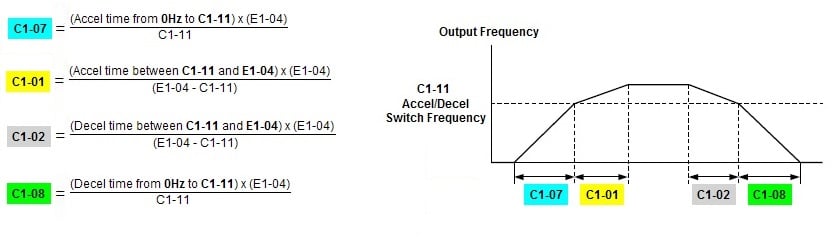

The acceleration and deceleration times are scaled from 0Hz to E1-04. Therefore, the equations below are needed to calculate the desired acceleration and deceleration times based on C1-11. If necessary, use the calculator (Excel spreadsheet) in the attachment section. Refer to the diagram and follow the steps below to setup an automatic switching of acceleration and deceleration times based on a specific frequency level.

Example The drive needs to accelerate from 0Hz to 45Hz in 15 seconds and from 45Hz to 60Hz in 25 seconds and decelerate at the same rates and frequencies. Set the following:

|

|

||

| FP605, GA800, GA800 Configured, GA500, A1000, U1000 Industrial, V1000, |

|

||

| Advanced Random Rotary Knife with Cam Blend, Air Compressor, Blister pack Thermoformer, Cartoner, Centrifuge, Conveyor, Crane/Hoist, Dynamometer, Elevators and Escalators, Extrusion, Fans/Blowers, Feed To Length, General Machinery, HVAC, Irrigation, Labeler, Laundry, Linear Flying Shear, Machine Tool, Mixer, Other, Packaging, Palletizer, Precision Grinding, Pump, Punch Press, Rotary Knife, Rotary Placer, Rotary Table Indexer, Screw Feeder, Semiconductor, Solar Cell Tabbing and Bussing, Solar - Textured Etching, Synch-Belt, Textile, Winding, |

|

||

| Calculator - A1000, V1000, U1000.xlsx

|

| Last Modified Date: 11-27-2023 |

|

|