|

||

|

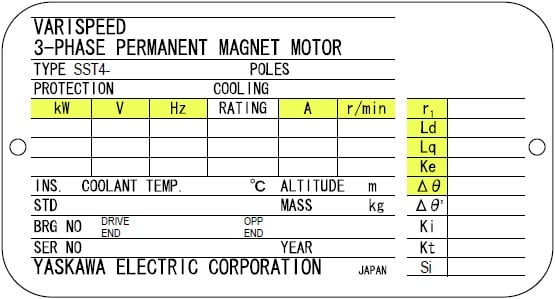

A permanent magnet (PM) motor is constructed with magnets in or around the rotor and requires a VFD to accelerate up to full speed or run at a specific RPM. Some of the advantages with this type of motor include high efficiency, light weight, and excellent torque control. There are certain Yaskawa Series drives which have the capability to run a permanent magnet (PM) motor. It is crucial the drive is setup correctly and an Auto-Tune performed to maximize performance and prevent damage to the motor compoents. For more information on permanent magnet motor control in general, refer to the following documents:

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

To Auto-Tune and program a Yaskawa Series drive for a permanent magnet (PM) motor, follow the steps below:

V1000 Drives Since V1000 drives do not have an Auto-Tune function, the E5-xx parameters will manually have to be entered. Set or verify the following:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||

| FP605, FP605 Configured, GA800, GA800 Configured, GA500, HV600, HV600 Configured, A1000, A1000 Configured, L1000, U1000 Industrial, U1000 Industrial Configured, U1000L, U1000 Oil and Gas, V1000, V1000-4X, Z1000, Z1000 Configured, Z1000U, Z1000U Configured, |

|

||

| Advanced Random Rotary Knife with Cam Blend, Air Compressor, Blister pack Thermoformer, Cartoner, Centrifuge, Conveyor, Crane/Hoist, Dynamometer, Elevators and Escalators, Extrusion, Fans/Blowers, Feed To Length, General Machinery, HVAC, Irrigation, Labeler, Laundry, Linear Flying Shear, Machine Tool, Mixer, Other, Packaging, Palletizer, Precision Grinding, Pump, Punch Press, Rotary Knife, Rotary Placer, Rotary Table Indexer, Screw Feeder, Semiconductor, Solar Cell Tabbing and Bussing, Solar - Textured Etching, Synch-Belt, Textile, Winding, |

| Last Modified Date: 02-10-2025 |

|

|

.jpg)

.jpg)

.jpg)

.jpg)