Topic Description

| |

|

An Hbb or HbbF (Safe Torque OFF) will occur on A1000, U1000, and V1000 (with Dual Safe Disable Option) drives when one or both of the safety inputs (H1 and H2) is open (OFF). The drive will coast to a stop and remain in a "not ready" state until both of the safety inputs (H1 and H2) return back to a closed (ON) state. The RUN command will then need to be cycled to start the drive.

Note:

Use the table below to determine when an Hbb or HbbF condition will occur:

| Input Status |

Safe Disable Status |

Keypad Display |

Drive Output

Status |

Modbus/Memobus Register

00CBH (Alarm Contents 5) |

| Terminal H1 |

Terminal H2 |

Terminals DM+ DM- |

Digital Output

Minor Fault (H2-0x = 10) |

Bit A |

Bit B |

ON

(Closed) |

ON

(Closed) |

Not Active |

Not Active |

- |

Drive Ready |

0 |

0 |

OFF

(Open) |

ON

(Closed) |

Not Active |

Active |

HbbF (Flashing) |

Safety Status |

1 |

0 |

ON

(Closed) |

OFF

(Open) |

Not Active |

Active |

Hbbf (Flashing) |

Safety Status |

1 |

0 |

OFF

(Open) |

OFF

(Open) |

Active |

Active |

Hbb

(Flashing) |

Safety Status |

0 |

1 |

Note: V1000 (with Dual Safe Disable option) drives do NOT have DM+ and DM- terminals.

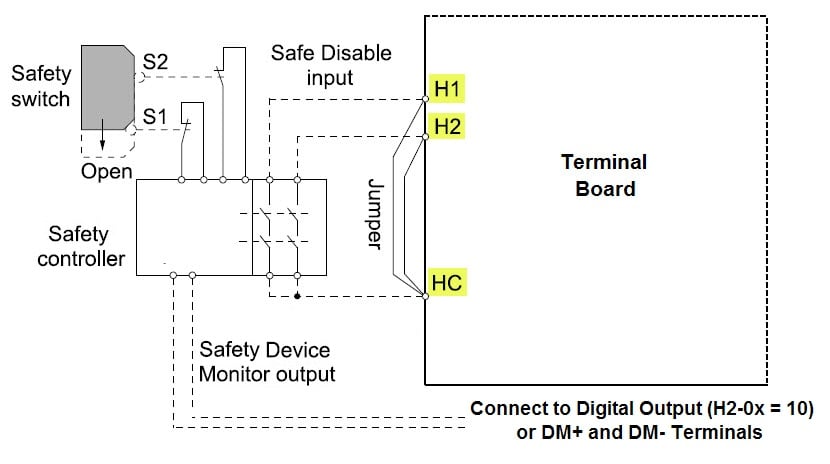

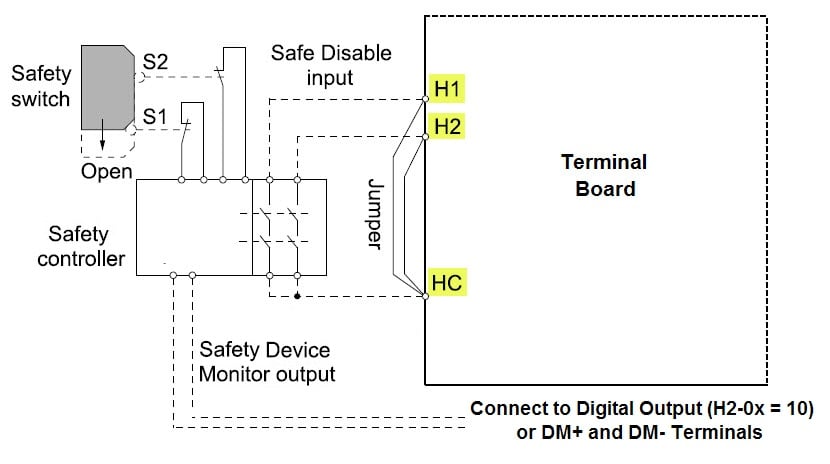

The image below illustrates the H1, H2, and HC (common) connections on the terminal board and the factory jumpers if an external safety input is NOT present.

|

Resolution

| |

|

Follow the steps below for troubleshooting an Hbb or Hbbf condition on A1000, U1000, and V1000 (with Dual Safe Disable Option) drives:

External Safety Input NOT Present (Factory Jumpers in Place)

-

Verify jumpers are present on H1/HC and H2/HC terminals and connections are tight and secure.

-

Verify jumper S3 (A1000, U1000) or jumper S6 (V1000) is set to SINK. If Hbb or HbbF is still occuring, proceed to step 3.

- Remove power to the drive and wait at least 15 minutes.

-

Caution: It is recommended to verify 10VDC or less is present on the DC bus before performing any service work.

-

Remove jumpers and ALL control wiring (digital inputs, communication, etc.). Apply power and check for 24VDC between H1/HC and H2/HC.

-

If 24VDC is NOT present, the issue may be within the terminal board, control board, or more internal to the drive. It is recommended to have an ASP (Authorized Service Provider) perform any repairs.

-

If 24VDC is present, add non-factory jumper wires between H1/HC and H2/HC terminals.

-

If Hbb or Hbbf does not clear, the issue may be within the terminal board, control board, or more internal to the drive. It is recommended to have an ASP (Authorized Service Provider) perform any repairs.

External Safety Input Present (NOT Using External 24VDC)

-

Verify connections are tight and secure on H1, H2, and HC terminals and an external 24V is NOT being provided.

-

Verify safety input closure with external safety device.

-

Verify jumper S3 (A1000, U1000) or jumper S6 (V1000) is set to SINK. If Hbb or HbbF is still occuring, proceed to step 4.

- Remove power to the drive and wait at least 15 minutes.

-

Caution: It is recommended to verify 10VDC or less is present on the DC bus before performing any service work.

-

Remove connections on H1, H2, HC terminals and ALL control wiring (digital inputs, communication, etc.). Apply power and check for 24VDC between H1/HC and H2/HC.

-

If 24VDC is NOT present, the issue may be within the terminal board, control board, or more internal to the drive. It is recommended to have an ASP (Authorized Service Provider) perform any repairs.

-

If 24VDC is present, add non-factory jumper wires between H1/HC and H2/HC terminals.

-

If Hbb or Hbbf does clear, troubleshoot safety controller or look for a open safety input.

-

If Hbb or Hbbf does not clear, the issue may be within the terminal board, control board, or more internal to the drive. It is recommended to have an ASP (Authorized Service Provider) perform any repairs.

External Safety Input Present (Using External 24VDC)

-

Verify connections are tight and secure on H1, H2, and HC terminals.

-

Verify safety input closure with external safety device.

-

Verify jumper S3 (A1000, U1000) or jumper S6 (V1000) is set to SOURCE. If Hbb or HbbF is still occuring, proceed to step 4.

- Remove power to the drive and wait at least 15 minutes.

-

Caution: It is recommended to verify 10VDC or less is present on the DC bus before performing any service work.

-

Remove ALL control wiring (digital inputs, communication, etc.) except the H1/H2/HC wires. Apply power and verify 24VDC is preset across H1/SN and H2/SN terminals.

-

If external 24VDC is NOT present, troubleshoot safety controller or look for an open safety input.

-

If external 24VDC is present, the issue may be within the terminal board, control board, or more internal to the drive. It is recommended to have an ASP (Authorized Service Provider) perform any repairs.

|

All Applications

| |

|

| Advanced Random Rotary Knife with Cam Blend,

Air Compressor,

Blister pack Thermoformer,

Cartoner,

Centrifuge,

Conveyor,

Crane/Hoist,

Dynamometer,

Elevators and Escalators,

Extrusion,

Fans/Blowers,

Feed To Length,

General Machinery,

HVAC,

Irrigation,

Labeler,

Laundry,

Linear Flying Shear,

Machine Tool,

Mixer,

Other,

Packaging,

Palletizer,

Precision Grinding,

Pump,

Punch Press,

Rotary Knife,

Rotary Placer,

Rotary Table Indexer,

Screw Feeder,

Semiconductor,

Solar Cell Tabbing and Bussing,

Solar - Textured Etching,

Synch-Belt,

Textile,

Winding,

|